Tq. Converter Stall Speed

Switching to a higher stall-speed torque converter can provide the benefit of increased launch RPM and better low-speed acceleration. Once your vehicle is up and moving, though, a different converter will have little effect. Like any other performance tuning variable, converter stall-speed should be closely matched to your vehicle and power-train requirements. Also, a torque converter may not necessarily deliver the advertised stall speed due to differences in engine torque output and vehicle chassis conditions. After-market torque converters vary greatly in their quality and coupling efficiency. However, no converter should have to reach its advertised stall RPM just to back out of your driveway or accelerate in city traffic, as is a common misconception about higher-stall-speed torque converters. In fact, a properly designed mild after-market converter (i.e. 2500 RPM stall-speed) should not feel much different than its OEM counterpart in everyday driving.

Stall speed should be selected so that the torque converter will reach its stall speed just before the engine starts it power-band (when torque output begins increasing sharply). Too much stall RPM will actually slow a car down by wasting part of the engine's useful power curve. A stock torque converter in an AOD equipped Mustang will produce a stall speed of about 1800RPM, while the stock 5.0L H.O. engine enters its power-producing stage slightly later. Therefore, a stall speed of 2500 RPM is best for most stock and mildly modified 5.0L HO applications. Stock 5.0L Mustang AOD-E torque converters stall at about 2400 RPM, and will provide significant improvements over an AOD converter. Vehicles with significantly altered valve events (i.e. large camshafts and/or huge valves) may benefit from stall speeds as high as 3000RPM or more depending upon configuration and torque curve. In such cases, it is best to consult your camshaft supplier or engine builder for best results.

For AOD transmissions (as well as C-4 and C-6 applications) there are a number of vendors providing high quality torque converters in many different configurations. As mentioned in the AOD section, Art Carr's converters require use of their special input shaft for the AOD and are available in a variety of stall speeds and sizes. Precision Industries also makes converters in both "lockup" and "non-lockup" varieties for the AOD with stall speeds to order. Baumann Engineering can also furnish high quality custom built converters for Ford transmissions at competitive prices. Before purchasing any torque converter, we suggest that you get objective recommendations from other performance enthusiasts and avoid using purchase price as the sole selection criteria.

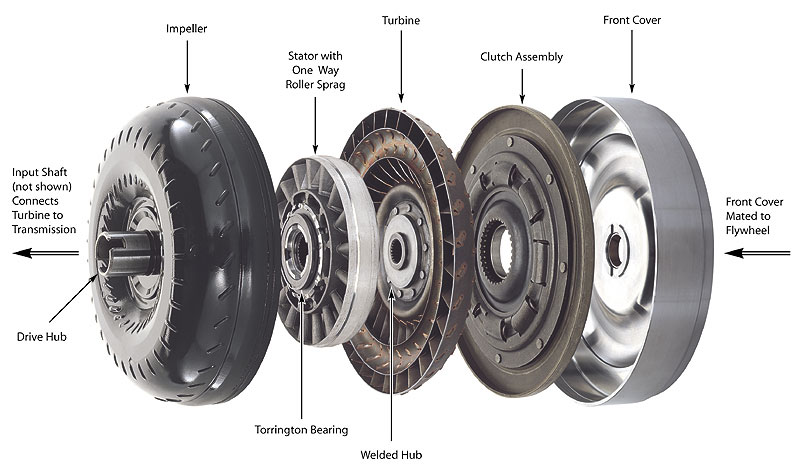

As with the E4OD and A4LD transmissions, few vendors have yet to produce higher stall-speed torque converters for the AOD-E/4R70W transmission. However, Baumann Engineering can provide a custom-built torque converter for these and most other applications. In the case of converter clutch style transmissions, such as the AOD-E/4R70W, E4OD and A4LD, we rarely advocate removing the lockup clutch assembly from the torque converter. Therefore, they provide their converters with new heavy-duty lockup clutch assemblies. This allows you to selectively control converter lockup with the Baumannator TCS™ or even external switches if desired, thereby providing maximum efficiency and versatility with no adverse effect on vehicle performance.

How do I choose the right stall speed?

Under ideal circumstances you should select a converter that stalls approx 700 rpm below peak torque. This will set the converter and the transmission's gearing to do their job, until you reach peak hp or shift points.

For street use we never recommend a stall speed higher than 3000 to 3500 rpm depending on the rear end ratio and your normal driving rpm. If your normal 55 to 60 mph cruising rpm is at 2500 rpm, you don't want a convertor that is any higer. What you do want is the convertor to be highered up at that speed in order to avoid the heat buildup a converer generates when it is working.

It is a general misunderstanding that a vehicle will not move until the stall speed is reached. This is not the case. With a 3000 rpm stall this vehicle is drivable at any rpm, it may seem a bit sluggish or lazy until you reach 3000 rpm.

The SC makes peak torque somewhere from 2500-3000 rpm depending on what mods you have. This calls for a 1800-2300rpm stall for most applications. Unlike naturally aspirated motors, the SC makes all of it's power down low. By stalling the motor ABOVE IT'S EFFECTIVE POWER BAND, you are wasting most of it's effective power through slippage in the torque convertor.

I suggest 2,800 rpm stall converter in a SC only if you wish to drive at or above the peakTorque rmp of the engine. In other words I would not recommend a high stall converter in a SC if you intend to use it as a dailydriver. It is nearly impossible to keep the rear end from breaking loose. I am exchanging it for the 2,200 rpm converter. http://www.protorque.com, Precission Industries

Do you agree with the above statement. If not please tell me why.

Garage

Garage

former owner - Extreme Procharger Marauder

former owner - Extreme Procharger Marauder . My new BC Auto 3500 stall converter is far superior than my previous PI 3000 Stallion, hands down.

. My new BC Auto 3500 stall converter is far superior than my previous PI 3000 Stallion, hands down.